Responsible Recycling

When you’re done with your vehicle, be aware of who you’re selling it to…

It’s An Important Decision

Where you send your vehicle when it reaches the end of the road can make the difference between increased environmental damage or responsible earth stewardship. The truth is, not everybody handles end-of-life and accident affected vehicles the way our members do.

It’s almost unbelievable that in a community where most of us care about our environment there are some scrap operations who buy and crush cars, allowing toxic fluids and heavy metals to escape into the soil and groundwater. Or they export the pollution to various Middle Eastern or African countries. They pay no regard to the damage they’re doing to the environment.

Retire Your Ride recyclers are committed to ensuring their practices, facilities and training meet the requirements of the Australian Certified Automotive Recyclers program. They represent the best pathway to ensuring your end-of-life vehicle (ELVs) is processed properly. Each vehicle goes through a methodical process to maximize reclamation and minimize environmental impact. They are committed to investing in the training and equipment needed to ensure each and every vehicle is handled in an environmentally responsible manner.

Here’s What We Do With Your Vehicle

Your car is the largest and most recyclable product you own. No sorting required – the recyclers that work with Retire Your Ride will reuse and recycle 80% of your vehicle and will make sure the remaining materials are disposed of responsibly.

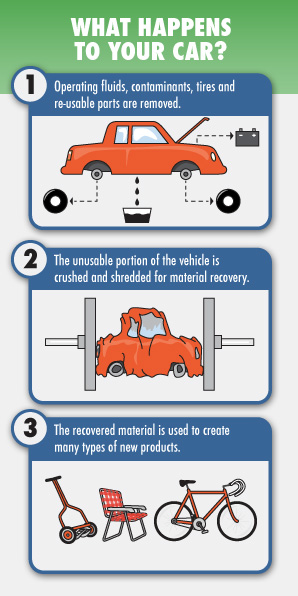

Once your vehicle has been picked up by one of Retire Your Ride’s participating auto recyclers, it will be recycled at their facility in three stages:

- Pre-treatment: drainage of operating fluids

- Parts Re-use: dismantling of parts and components

- Recycling of Materials

Stage One – Pre-Treatment

Preparation of a vehicle for dismantling is vital to proper recycling. This includes the drainage of operating fluids such as oil, coolants, refrigerants and fuel, and the removal of the fuel tank, battery and tyres. It is critical that the draining and proper collection of fluids is performed to prevent any groundwater contamination. The average volume of operating fluids in a car is approximately 34 litres:

| Engine oil | 5.0 litres |

| Transmission oil | 1.5 litres |

| Final drive oil | 1.1 litres |

| Steering gear oil | 0.8 litres |

| Coolant | 4.2 litres |

| Fuel | 20.5 litres |

Once the fluids and other materials have been removed, they are re-used or responsibly disposed of.

OILS AND GREASES:

Removed to a licensed recycling facility or used for energy recovery in approved used oil furnaces where allowed.

COOLANT, FUEL, WINDSHIELD FLUID:

Re-used by the auto recycler, or removed to a licensed recycling facility.

REFRIGERANTS (CFCS, HCFCS):

Air-conditioning systems are required to be evacuated by a trained technician. The used refrigerant is re-used or removed by a licensed recycling facility.

GAS TANKS:

Punctured, drained and recycled for the metals and increasingly recycled for its plastic content.

BATTERY:

This component is either re-sold or removed by a licensed recycling facility.

TYRES:

Good quality tyres are reused. All States now have a scrap tyre stewardship program to properly manage tyres and create value added end products.

Stage Two – Parts Re-use

Depending on their condition and sales potential, parts and components are dismantled, reconditioned and sold to customers. This minimizes the need for manufacturing new parts.

Depending on their condition and sales potential, parts and components are dismantled, reconditioned and sold to customers. This minimizes the need for manufacturing new parts.

Parts which are commonly re-used include engines, transmissions, whole front and back ends, body panels, and wheels.

To find Green Recycled Parts near you see Delivery Partners

Stage Three – Recycling of Materials

Once all the fluids have been drained and the re-usable parts have been removed, the automotive recycler employs the services of an automobile crusher to flatten the vehicle shell. These flattened shells are shipped to shredders which pulverize the car into fist-sized pieces in minutes. The valuable ferrous and non-ferrous metals are removed magnetically, and with complex floatation systems. The non-metallic components, known as Auto Shredder Residue (ASR) or fluff, are landfilled. ASR is composed of rubber, plastics, fabric, dirt, foam, glass and metal particles. That is why it is critical to ensure that the hazardous components are recovered before the car is crushed and shredded. Research continues to determine ways to reduce the amount of ASR diverted to landfills, both at the manufacturing and recycling stages in the life of a vehicle.